Magnets stirring usually involves a polymer coated AlNiCo or ferrite magnet and relies on the establishment of a liquid flow induced by centrifugal forces. These flow patterns involve a downward liquid motion towards the centre and an upward motion at the vessel wall. However, the strength of the magnetic separator decreases rapidly over a period of months when subjected to the high temperatures of microwave synthesis and the limited size of the vessel restricts the establishment of flow patterns

Separator is suitable for wet magnetic particle size below 3mm magnetite, pyrrhotite, roasted ore, ilmenite and other materials, but also for iron work coal, non-metallic minerals, building materials and other materials, industrial industry's most widely used one of the highly versatile models.

Tuesday, March 1, 2016

Thursday, February 25, 2016

Stirring microwave synthesis

It is next to impossible to achieve good mixing with traditional magnetic stir bars in the cylindrical vessels used in microwave synthesis. So scientists in Austria have designed a new stir bar.magnetic filter bars is becoming more popular thanks to the dramatically reduced reactions times and improved yields it offers. However, as the majority of these reactions involve a small narrow reaction vessel, traditional horizontal stir magnet bars often result in inefficient mixing which can cause temperature gradients to develop and reduce product yields.

Saturday, February 20, 2016

Test your compass

If you are not sure where your magnetic grid North is, you can determine which end of the compass needle is the North end by going outside at noon, when the sun is at the highest point of the sky. Hold the compass flat in your hand with the South end of the compass nearest to your body.Note the position of the compass needle. If you live North of the Earth’s equator, the North end of the needle will be pointing towards you and the South end of the needle will be pointing toward the sun. If you live South of the equator, the South end of the compass needle will be pointing towards you

Monday, February 15, 2016

Features Magnetic Separator

The magnetic particles in a magnetic separation equipment, except by the magnetic force, but also by the role of competitiveness. Competitiveness can be defined as the direction opposite to the magnetic force of all mechanical forces, including gravity, centrifugal force, inertia force and the hydrodynamic resistance and the like. In the magnetic separation process, the magnetic force of the magnetic particles is a collector, the collector also known as magnetic force; competitiveness of the magnetic particles from the magnetic stir bars, is also known from the force. Obviously, a necessary condition for the magnetic particles and non-magnetic particle separation is greater than the magnetic force of the magnetic particles suffered competitiveness

Wednesday, February 10, 2016

The role of magnetic separator

magnetic separator for quartz sand is divided into two categories, permanent magnetic separator, the more high-quality ferrite material or rare earth magnets composite, cylinder table before the average magnetic induction 80-400mT. Due to the development of technology, can be made into a roll-like magnetic separator, magnetic field strength is increased to 1650mT has the highest high frequency vibrating sieve intensity Found

Friday, February 5, 2016

Separator basic introduction

recycling cross belt magnetic separator is one of the most extensive, highly versatile models in the industry for having a separation of the magnetic material difference. Magnetic Separator is widely used in mining, timber, ceramics, chemical, food and other industries. For mining, the magnetic separator machine for size 50mm or less manganese ore, magnetite, pyrrhotite, roasted ore, ilmenite, hematite limonite and other materials wet or dry magnetic separation, but also for coal , non-metallic minerals, building materials and other materials in addition to iron work

Saturday, January 30, 2016

Magnetic separator is suitable for having a separation, powder separators material widely used in other difference workshop recycling, timber, mining, ceramics, chemical, food, etc., for a particle size below 3mm magnetite, pyrrhotite wet magnetic separation, roasting ore, ilmenite and other materials, also used in addition to iron work coal, non-metallic minerals, building materials and other materials, is the industry's most widely used one of the highly versatile models. Magnetic separator according to the classification can be divided into drum separator machine, roll machine and roller dry magnetic separator machine

Monday, January 25, 2016

Magnetic force of drawers

Depending on the temperature of the economy in addition to iron and other needs, we selected materials prepared for you a variety of options, neodymium, samarium cobalt, ferrite, alnico magnet bars magnet has, on the whole magnetic the stronger the material can absorb iron particles smaller, more to protect the safe operation of material purity and downstream processing equipment. drawer magnet with various forms of door to avoid dust leakage, there with sealing gasket, useful locking fasteners, and fully guarantee the workers' working environment, but also to facilitate the switch, clean up attracted iron impurities

Wednesday, January 20, 2016

Magnetic Drawer Box

magnet drawers with a single layer or multi-layer magnetic frame can be extracted and cabinet components. If you want a good addition to iron the best choice multilayered, because multiple layers can effectively slow down the flow through the material, but also allows the agglomerated material broken off, but also to avoid the drum magnets is not strong corner. Our manufacturing magnetic box is a favorite of many, its wide use, and easy to clean, you can use a variety of sizes and connections go into production lines, whether pipe or chute-type formula. We can according to customer requirements as far as possible the natural magnetic box, precision mounted to the pipeline

Friday, January 15, 2016

Application of dry magnetic separator

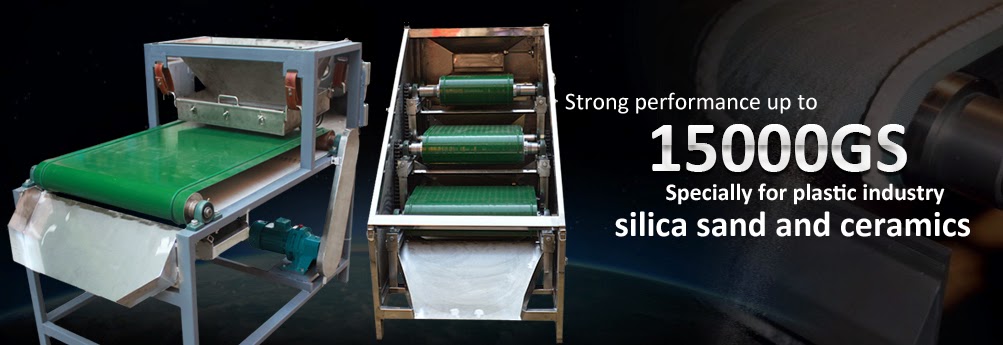

Ore dry magnetic separators of the most significant features of a high magnetic field strength, the work of up to 13,000 to 15,000 Gauss magnetic field, somewhat different depending on the model differences, to the various common ferromanganese weakly magnetic minerals effectively sorting.

Ore dry magnetic separator machine designed for small roll diameter, multi-roll combination of models to suit the low dry high intensity magnetic separator speed operation, effectively narrow election sub surface, shallow depth sorting, a single mineral recovery beneficiation of low operating characteristics, the relationship between the multi-roll in series.

Sunday, January 10, 2016

Red limonite dry magnetic separators is high facefield on strength

Red limonite dry magnetic separators is high facefield on strength.Red limonite magnetic separation equipment for magnetic separation operation, mainly for weakly magnetic minerals and non-metallic mineral beneficiation iron work.

Red limonite dry magnetic separator machine not only as a coarse weakly magnetic iron ore sorting preselection roughing device. For some minerals can also be used as the main sorting equipment. Its advantages are simple process, to facilitate the production management, the drawback is the low grade concentrates.

Tuesday, January 5, 2016

What is dry magnetic separator

Dry magnetic separation is carried out sorting machinery for dry magnetic separation of magnetic minerals, with respect to wet magnetic separator to use liquid as a diluent to improve the terms of separation efficiency when sorting mineral, dry magnetic separator is required to be Sorting the mineral drying, particles can move freely between, into independent free state, otherwise it will affect the magnetic effect, and even the consequences can not be sorted.

Dry magnetic separator equipment is commonly used in iron and manganese equipment, the mainstream of the strong magnetic separator beneficiation equipment. Dry magnetic separation is carried out sorting machinery for dry magnetic separation of magnetic minerals, with respect to wet magnetic separator to use liquid as a diluent to improve the terms of separation efficiency when sorting mineral, dry magnetic separator is required to be Sorting the mineral drying, particles can move freely between, into independent free state, otherwise it will affect the magnetic effect, and even the consequences can not be sorted. Dry magnetic separator machine is suitable for wet magnetic particle size below 3mm magnetite, pyrrhotite, roasted ore, ilmenite and other materials, also used in addition to iron work coal, non-metallic minerals, building materials and other materials.

Friday, January 1, 2016

How to choose a good magnetic separator

magnetic separator mining equipment is an indispensable tool demagnetization, and then use the intensity magnetic separation to screen different mineral composition. Separator according to the type of points, there are permanent magnetic separator and magnetic separator. In accordance with the wet ore to points can be divided into wet and dry magnetic separator machine! Most are then wet it with a wet magnetic separator process relies on water medium separator, German art magnetic sorting machine is magnetic in electromagnetic separator!

Drawbacks of dry magnetic separators machine: bearing lubrication is bad, the cylindrical body is formed of material clogging stuck phenomenon, publish noisy fan leaves smashing sound when worn! Buy a good one is to see the work first separator device itself, the handling capacity, long service life, different works, the machine is not the same, Jiang Zi specific arrangements necessary!

Subscribe to:

Posts (Atom)