Separator is suitable for wet magnetic particle size below 3mm magnetite, pyrrhotite, roasted ore, ilmenite and other materials, but also for iron work coal, non-metallic minerals, building materials and other materials, industrial industry's most widely used one of the highly versatile models.

Tuesday, July 28, 2015

Dry drum magnetic separator, the farther away from the cylinder surface

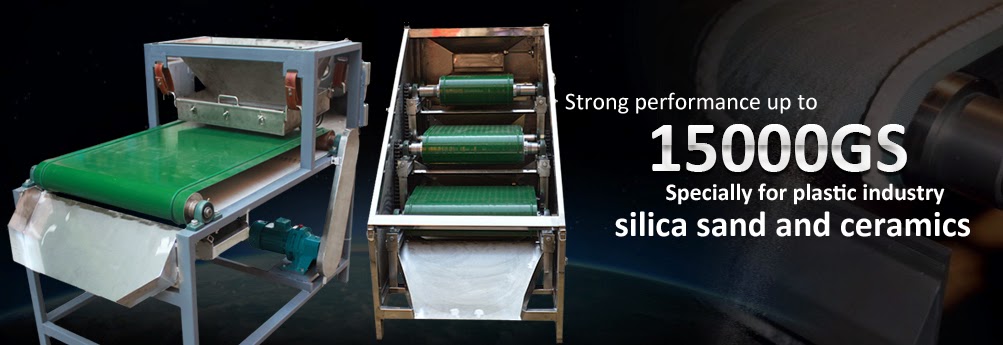

Dry drum magnetic separator, the farther away from the cylinder surface, super powerful magnet decay, streams too thick will cause the magnetic particles and non-magnetic particles are mixed with each other, affecting the separation efficiency of ore, if realized particles on the belt single layer distribution is ideal. Requires dry pre-election increase in the material layer flat feeder, make full use of the effective width of the belt, and the dry material selection thin and evenly to ensure dry separation effect. Efficient magnetic parting device makes use of strong magnetic forces Drum Separator sorting weak magnetic minerals become a reality.

Tuesday, July 21, 2015

Dry drum magnetic separator is the successful development

Dry drum magnetic separator is the successful development of our new high-efficiency magnetic parting device. Magnetic system all use high quality ferrite materials and rare earth NdFeB materials produced through wonderful open magnetic circuit plan, the maximum magnetic induction tube table sorting area to reach 0.8T above, magnetic field strength is customary machine 3 -5 times the magnetic force of the magnetic sub-constituency can reach the level of electro magnetic super powerful magnet separator. Sorting cylinder mining durable stainless steel refining; separation of mineral oscillated feeder evenly to the upper part of the sorting drum rotating cylinder barrel stripped the non-magnetic materials, magnetic materials have been strong magnetic forces suction effect to the cylinder, it is convenient to use sub-ore plate, precisely the magnetic and non-magnetic materials respectively.

Tuesday, July 14, 2015

Dry magnetic separator Scope

Dry magnetic separator Scope:

1, coarse disseminated form of hematite, limonite, mirror, iron ore, manganese ore and all weak magnetic minerals selected purification.

2, non-metallic minerals (andalusite, sillimanite, kyanite, garnet, feldspar, quartz, rutile, zircon, corundum, diamond, etc.) in addition to iron raw materials and products, in addition to titanium, cleaning and other refined processing.

3, the magnetic separation equipment main purposes: the election of anhydrous iron work area; refractory materials and other materials in addition to iron work.

Dry magnetic separator features: the disposal of a large amount of equipment, sorting mineral grain wide-scale, high precision parting, not obstruction; structure is simple, convenient protection, power consumption is only 20% of electromagnetic strong magnetic separator.

1, coarse disseminated form of hematite, limonite, mirror, iron ore, manganese ore and all weak magnetic minerals selected purification.

2, non-metallic minerals (andalusite, sillimanite, kyanite, garnet, feldspar, quartz, rutile, zircon, corundum, diamond, etc.) in addition to iron raw materials and products, in addition to titanium, cleaning and other refined processing.

3, the magnetic separation equipment main purposes: the election of anhydrous iron work area; refractory materials and other materials in addition to iron work.

Dry magnetic separator features: the disposal of a large amount of equipment, sorting mineral grain wide-scale, high precision parting, not obstruction; structure is simple, convenient protection, power consumption is only 20% of electromagnetic strong magnetic separator.

Tuesday, July 7, 2015

Dry drum magnetic separator is suitable for

Dry drum magnetic separator is suitable for sand mining, iron ore and other iron-poor roughing fewer raw materials. Is sand, sand and other essential machinery containing a small amount of raw iron election dry iron.

Dry magnetic separator magnetic system, using high-quality ferrite material or rare earth magnets composite made of tube sheet average magnetic induction intensity of 1000 ~ 6000GS. The separator has a simple structure, large capacity, easy to operate, easy to maintain. Dry magnetic separator is ideal for arid regions, dryland magnetite mining and utilization has opened up a new way.

Dry magnetic separator magnetic system, using high-quality ferrite material or rare earth magnets composite made of tube sheet average magnetic induction intensity of 1000 ~ 6000GS. The separator has a simple structure, large capacity, easy to operate, easy to maintain. Dry magnetic separator is ideal for arid regions, dryland magnetite mining and utilization has opened up a new way.

Subscribe to:

Posts (Atom)