Separator is suitable for wet magnetic particle size below 3mm magnetite, pyrrhotite, roasted ore, ilmenite and other materials, but also for iron work coal, non-metallic minerals, building materials and other materials, industrial industry's most widely used one of the highly versatile models.

Friday, November 27, 2015

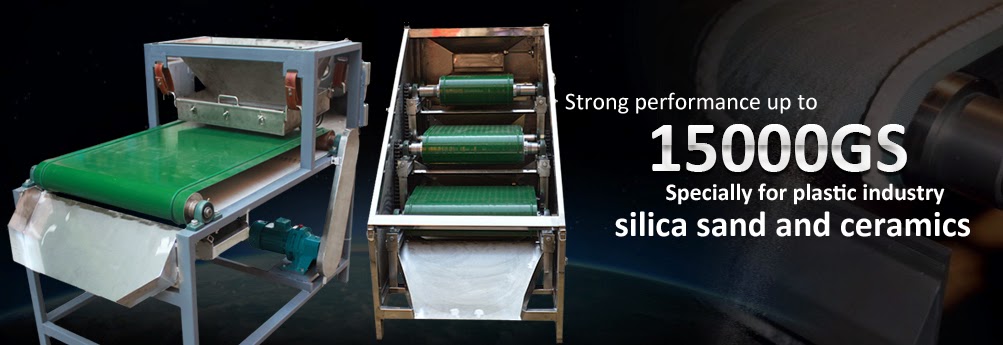

Dry permanent magnetic drum separator

Dry drum magnetic separator is the successful development of our new high-efficiency magnetic separation equipment. Magnetic system used in all high-performance rare earth NdFeB material and making quality ferrite material, a cleverly open magnetic circuit design, tube table points to reach the maximum magnetic flux density constituency over 0.8t, magnetic field strength is a conventional magnetic machine 3 -5 times the magnetic force of the magnetic sub-constituency can reach the level of electromagnetic strong magnetic separatorr. Sorting cylinder mining durable stainless steel refining; sorting the upper mineral feeder evenly to the vibration to sorting through the barrel, rotation of the cylinder barrel stripped the non-magnetic material, the magnetic material by the strong magnetic force attracted to the cylinder, with sub-ore board easily and accurately the magnetic and non-magnetic material separation. Strong magnetic force with drum magnetic separator sorting weak magnetic minerals into reality. Equipment processing capacity, sorting mineral grain size range, high separation accuracy, non-blocking; simple structure, easy maintenance, power consumption is only 20% electromagnetic strong magnetic separator.

Tuesday, November 24, 2015

Classification Magnetic Separator

magnetic separator can be divided based on low magnetic field intensity magnetic separator, magnetic separator, high magnetic separator; magnetic field is generated in accordance with the method can be divided into electromagnetic separator and the permanent magnetic separator; in accordance with different structures and It can be divided into disc, drum, roll, loop, drum, turn cage and belt separator; by sorting methods can be divided into dry and wet magnetic separator.

It can be divided into downstream magnetic separator and semi-countercurrent separator:

Downstream Permanent dry drum magnetic separator, the moving direction coincides with the direction of the cylinder pulp direction of rotation or movement of the product. Pulp from the bottom of the magnetic system to mine box directly into the cylinder, the non-magnetic mineral particles and weak magnetic mineral particles discharged from the bottom of the gap between the two bottom cylinders between. Magnetic mineral particles absorbing the cylindrical surface, the cylinder is rotated together with the weak magnetic field at the edge of the magnetic system, the mine water discharge be landed to the concentrate tank. Structure downstream type magnetic machine is simple, large capacity, can also be more than one series, suitable for separators particle size 6 ~ 0mm of coarse ferromagnetic ore roughing and selection operations, or for the recovery of magnetic heavy media . Semi-Permanent Magnetic Drum Separator countercurrent to loose suspension ore slurry is entering the sorting space from underneath the tank, pulp direction of movement of the magnetic field strength is substantially the same direction, so that mineral particles can achieve high magnetic force of cylinder surface. In addition, the tailings from the tailings discharge hole on the floor, the height of this overflow surface can be maintained in the slurry tank level. The above two characteristics determine the semi-countercurrent type magnetic separator concentrate obtained high quality and metal recovery. It is widely and to deal with micro-fine (less than 0.2mm) of ferromagnetic ore roughing and selection operations. This separator can be more than one series, improve concentrate grade.

Thursday, November 19, 2015

Applications drum magnetic separator

dry drum magnetic separator is suitable for wet magnetic particle size of less than 3mm pyrrhotite, magnetite, roasted ore, ilmenite and other materials; also used in addition to iron work coal, non-metallic minerals, building materials and other materials. magnetic system of magnetic separator using high quality ferrite material (or composite made with rare earth magnets), tube sheet average magnetic induction intensity of 100 ~ 600 mT. Depending on the user's needs, providing downstream, semi-countercurrent, countercurrent a variety of different table strong magnetic type. separator has a simple structure, easy handling capacity, operation and easy maintenance.

Tuesday, November 17, 2015

Drum Separator Introduction

Permanent Magnetic wet drum separator is suitable for mining metallurgical and mining beneficiation, concentrator and other enterprises and institutions and individual users, for sorting of fine particles of magnetic minerals, or to remove non-magnetic minerals mixed in magnetic minerals. Permanent Magnet Drum a field separator is a wet high intensity magnetic separator. A higher rare earth magnetic NdFeB magnetic blocks and blocks of the composite ferrite magnetic system with high magnetic field strength. The depth of the magnetic field, which is difficult demagnetization and other characteristics. Therefore, processing capability, strong production fluctuations adaptability, good sorting effect.

Wednesday, November 11, 2015

Routine maintenance dry magnetic separator is also very important

Routine maintenance dry magnetic separators is also very important, permanent magnet dry magnetic separator strength due to its own requirements and conditions of work, its routine maintenance is very important. Especially oil change maintenance is particularly important.

dry magnetic separator using the process should pay attention to:

① wear of the cylinder wall of the cylinder permanent magnet, if you find serious wear off after gum paste, should be promptly treated or re-hanging plastic.

② whether the iron and other debris falling into the cabinets, after finding should immediately clear.

③ motor overheating continuously variable transmission and a permanent cylindrical bearings, bearing temperature rise should not normally exceed 35 ° C, the maximum should not exceed 65 ° C.

④ drive belt tension situation, the tension level should be appropriate.

⑤ wear the belt, we found severe wear and tear, you should choose the length of the belt as a group to be replaced.

⑥ lubrication points if there is enough grease, CVT oil level is normal, if found inadequate, it should be promptly added.

The equipment should be regular maintenance, adjustment or replacement of parts affect its performance and enable equipment not working properly.

For when the permanent magnet dry magnetic separator maintenance of a regular job. A direct impact on the quality of maintenance work the permanent dry magnetic separator machine operating rate and service life. In order to detect deficiency eliminate hidden dangers, in order to ensure the normal operation of their machines, in addition to routine maintenance, but also the need for regular downtime, (recommended once a month) for important components such as the cylinder wall, cabinet, belts, etc. for careful examination, detailed records. Defects in order of priority according to the case to make appropriate arrangements for the handling and repair and overhaul program.

Friday, November 6, 2015

Technical characteristics of the dry drum magnetic separator machine

Technical characteristics of the dry drum magnetic separator machine:

● sorting magnetic drum thin-walled tube, stainless steel plate, stainless steel protective layer topical, not only conducive to sorting, and easy to replace, long life;

● multi-pole magnetic system, large wrap angle design, magnetic circumferentially arranged alternately, magnetic roll more often, good separation efficiency;

● NdFeB complex magnetic system, low operating cost, simple and reliable structure;

● Unique magnetic system design. High magnetic field strength, gradient, is conducive to the recovery of low-grade ore;

● transmission device uses electromagnetic speed, wide speed design, sorting drum line speed is adjustable, for a variety of mineral separation;

● A variety of tube diameter, a variety of widths designed to meet the processing requirements of a variety of magnetic separation of minerals;

● particularly suitable for extracting broken powdery sand lean ore enrichment and iron powder.

● sorting magnetic drum thin-walled tube, stainless steel plate, stainless steel protective layer topical, not only conducive to sorting, and easy to replace, long life;

● multi-pole magnetic system, large wrap angle design, magnetic circumferentially arranged alternately, magnetic roll more often, good separation efficiency;

● NdFeB complex magnetic system, low operating cost, simple and reliable structure;

● Unique magnetic system design. High magnetic field strength, gradient, is conducive to the recovery of low-grade ore;

● transmission device uses electromagnetic speed, wide speed design, sorting drum line speed is adjustable, for a variety of mineral separation;

● A variety of tube diameter, a variety of widths designed to meet the processing requirements of a variety of magnetic separation of minerals;

● particularly suitable for extracting broken powdery sand lean ore enrichment and iron powder.

Subscribe to:

Posts (Atom)